Useful Framework Describing Different Kinds of Production Systems and Processes

Chemical plants oil refiners etc 2. The batch system the continuous system and the project system.

Scrum Infographic Project Collaboration Work Agile System Scrum Stages Team Working Crea Procesos De Negocio Desarrollo De Software Planificacion De Proyectos

Types of Production Systems Chart Continuous and Intermittent Continuous System or Flow System.

. Connecting the inputs and outputs are. 1 Continuous System and 2 Intermittent System. Continuous process and batch.

Classification of production systems JOB SHOP PRODUCTION Job shop production are characterized by manufacturing of one or few quantity of products designed and produced as per the specification of customers within prefixed time and cost. Batch of products are realized with an superior amount respect to the real market request in order to keep a stock in case in the future there will be the need to change the production process. Bosenherg and Metzen 1992 give an account of the natural complexity of a production system relating the term to the development of manufacturing methods that establish guidelines and.

Manufacturing process flow design Method to evaluate the specific processes that raw materials parts and subassemblies follow as they move through the plant. Mass Production Mass production is the continuous production of items. Types of Production System in Operation Management OM Intermittent Production System Continuous Production System 1.

What are the two basic types of production systems. Intermittent Production System can be re-classified into. The production process is organized to provide the maximun flexibility.

Analytical Production System ii. In this article we review what a production process is the elements of deciding on the right one and the types of production processes available. In batch production the product goes through each stage of the process together before moving on to the next stage.

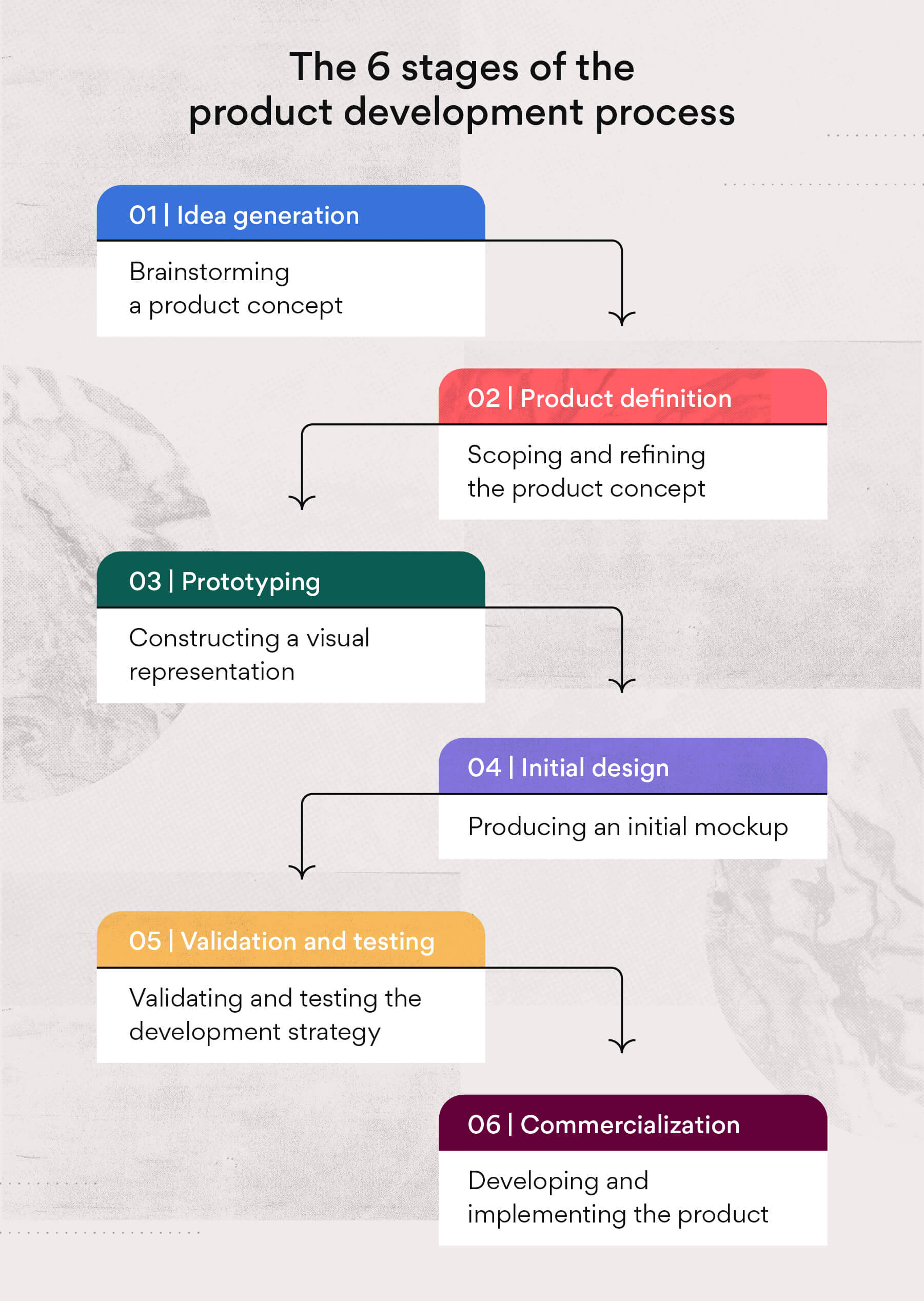

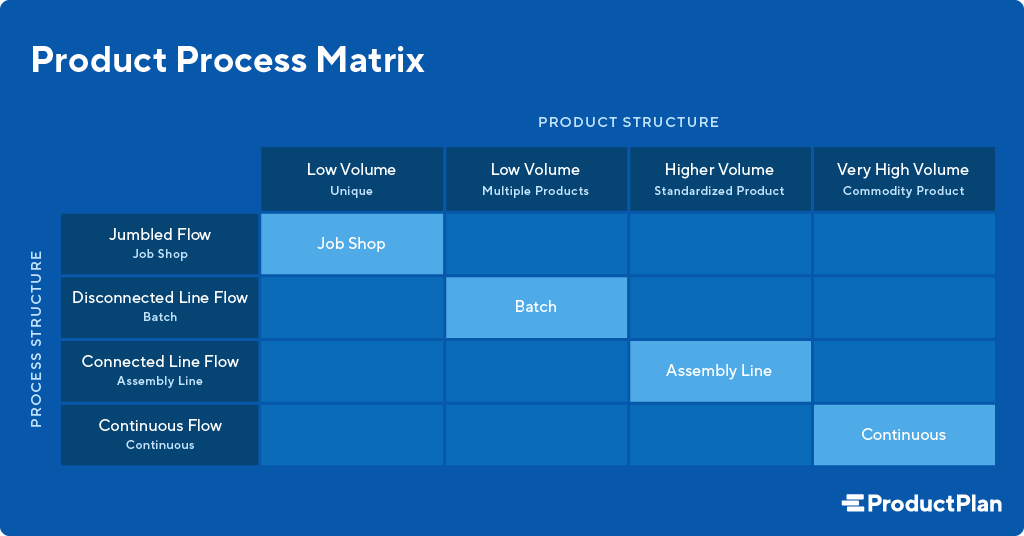

A framework depicting when the different production process types are typically used depending on product volume and how standardized the product is. Continuous System and Intermittent System with their advantage and disadvantage. Types of production systems There are three common types of basic production systems.

For example a guitar factory that has 12 workstations that continuously has one guitar at each station at a different stage of production. This involves a series of workstations that can all be in use at the same time. Production systems can be categorised into four types 1.

Mass production flows 2. Batch production is a method used to produce similar items in groups stage by stage. Process Production System can again be classified into.

Projects unit manufacture Problems confronting a production man are relevant with reference to a particular system. The production system can be viewed as a framework or skeleton of activities within which the creation of value can occur. The mass production system is product layout.

Mass production system In mass production components are produced in large quantities and minimal variety. Ment Framework is to prevent the occurrence of th e. Technologic cycle keep costant for long time period.

Product is the link between production and marketing. Production systems can be classified as Job Shop Batch Mass and Continuous Production systems. Soft science based on flexible technologies toyotism.

It provides system control through measurement comparison feedback and corrective action. Continuous flow type production system. Products are produced with the help of a single operation or use a series of operations.

Above four problem situations which result in non-holistic. At one end of the production system are the inputs and at the other end are outputs. Briefly the difference between the value of inputs and the value of outputs represents the value created through production activities.

The types of continuous production systems include. Inputs are transporting from one operation to another in the production process. Operations may be either manual or mechanical or chemical.

The example of continuous type of production system are. The production system according to nature and quantity of output can be broadly classified and the Types of Production System in Operation Management OM as. Normal and continuous process.

Production systems They are defined in accordance with the stages of the development of modern industry. Mass production or flow â line production system. The definition of production system must be sufficiently precise to be amenable to mathematical tools of operations research queuing theory networks and graph theory dynamic and linear programming stochastic processes and discrete event simulation so that limits on production system performance can be computed future behavior can be.

Conversion process includes operations actual production process. Continuous or Flow Production System can again be classified into. The 3 Types and Factors that Integrate It.

System design solu tions. Intermittent and non-intermittent process. The division of production management functions in to 5 ps product plant programme processes and people will provide useful conceptual framework for the various activities performed by production or operations manager.

Depending on methods of cost reduction organization technology level there are the following types. Here the company produces different types of large-scale products and stores them in warehouses until they are demanded in the market. There are two main types of production systems.

Meaning of production system Inputs include raw-materials machines man-hours components or parts drawing instructions and other paper works. A Production system Is any of the methods used in the industry to create goods and services from the use of different resources. The goal of the Production Sy stem Design and Deploy-.

Here are explain Types of Production Systems. Operations convert inputs into output. The right production process for each organization typically depends on factors like the technology available how many products the company needs to produce and organizational structure.

In the batch system general-purpose equipment and methods are used to produce small quantities of output goods or services with specifications that vary greatly from one batch to the next. Production can take a long time and can have higher production cost eg if special materials or tools are required. Depending on the flow characteristics there are four classes of the production system.

When one guitar is beginning production another is. Storage takes place after the receipt of inputs between one operation and the other and after the output.

The Organization Chart Provides A Framework For Creating All The Systems And Processes Of Your Business Business Org Chart Organization Chart Business Systems

Innovation Matrix For Product Managers Innovation Challenge Innovation Management Types Of Innovation

Production Planning And Control Ppc Plays An Important Role In Garments Manufacturing Business Maxi How To Plan Garment Manufacturing Industrial Engineering

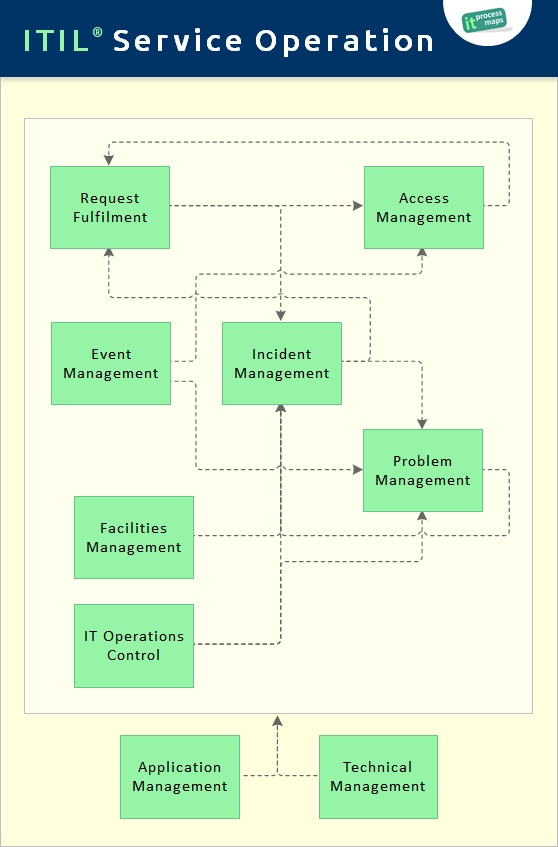

Itil Service Operation It Process Wiki

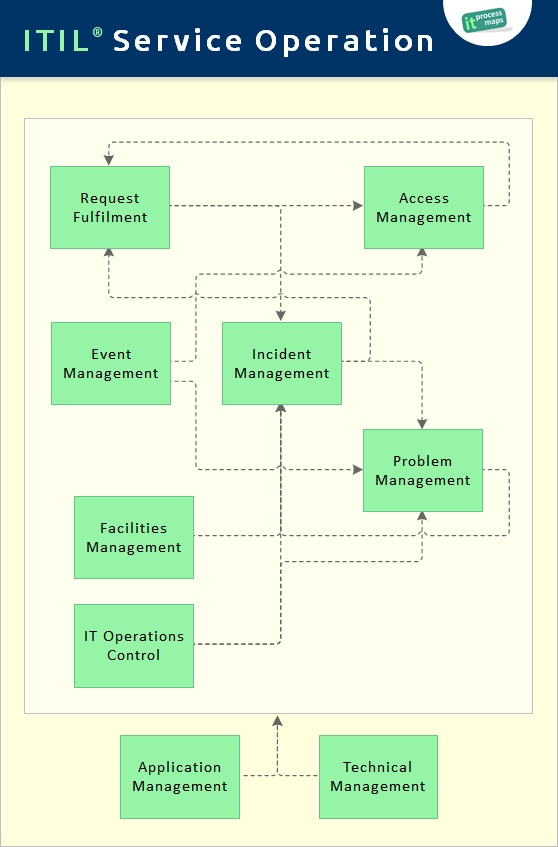

Itil Processes It Process Wiki

The Star Framework By Jay Galbraith Is A Widely Used Design Framework That Lists Five Catego Organizational Design Organizational Structure Business Analysis

Modern Portfolio Theory Markowitz Portfolio Selection Model Modern Portfolio Theory Investing Economics Definition

4 Designing For Manufacture Essential Manufacturing Sales And Marketing Data Science Online Learning

Resoluciondeproblemas Gestion Empresarial Administracion De Proyectos Procesos De Negocio

Itil Processes It Process Wiki

Incident Management It Process Wiki

Practical Requirements Engineering A Step By Step Approach 392 Page Pdf Document Flev In 2021 Requirements Engineering Change Management Agile Project Management

What Is Product Development The 6 Stage Process Asana

Share This Paper Big Data Data Science Data

Four Perspectives Of The Balanced Scorecard Change Management Business Systems Cause And Effect

Construction Organizational Chart Template Organisation Chart Of A Construction Company Constru Organizational Chart Organization Chart Flow Chart Template

What Is The Product Process Matrix Definition And Overview

Process Design Introduction To Operations Management

Value Stream Mapping Vsm Primer 19 Slide Powerpoint Flevypro Document Flevy Value Stream Mapping Software Development Business Development

Comments

Post a Comment